AAMA-Accredited Field Testing

This AAMA accreditation allows us to meet those project requirements that need a formal AAMA accreditation. We are accredited to perform the following field tests:

This AAMA accreditation allows us to meet those project requirements that need a formal AAMA accreditation. We are accredited to perform the following field tests:

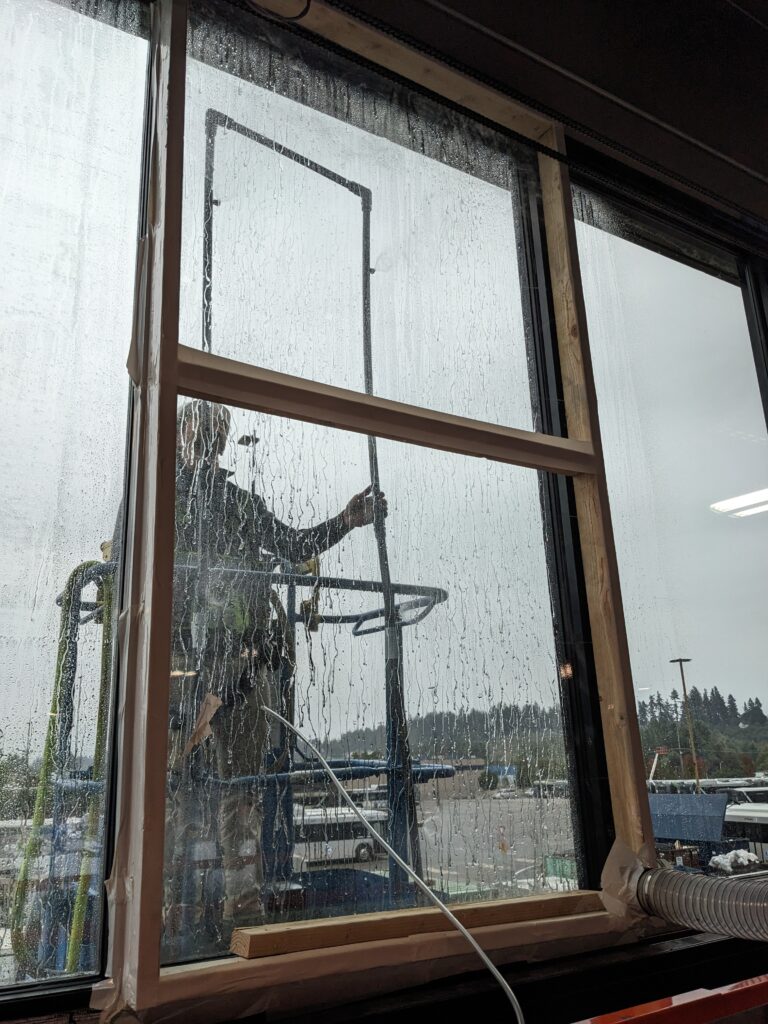

AAMA 501.2 – Hose Nozzle Water Spray Testing

The AAMA 501.2 is the standard for testing quality assurance and diagnostic water leakage field check of installed storefronts, curtain walls, and sloped glazing systems. It is designed to aid in the water-tight testing of large glass areas meant to be permanently closed, such as store fronts, curtain walls, and sloped glazing systems.

AAMA 501.2 is a standard published by the American Architectural Manufacturers Association (AAMA) that outlines procedures for hose nozzle water spray testing of windows, doors, and skylights. This test is designed to evaluate the water resistance and performance of these building components when subjected to water spray under controlled conditions.

Overview of the AAMA 501.2 testing procedure:

Test Setup: The test specimen (window, door, or skylight) is installed in a test chamber, which is typically equipped with a rack system to hold the specimen in place. The chamber also has provisions for the application of water spray.

Water Spray: The test involves directing a stream of water at the test specimen using a hose nozzle. The water is typically delivered at specified pressures and flow rates to simulate different wind-driven rain conditions.

Test Conditions: The test conditions may vary depending on the specific requirements or performance class being evaluated. This could include variations in water pressure, duration of the test, and the angle of water spray.

Observations: During the test, visual observations are made to detect any water leakage, penetration, or other signs of failure. This may involve inspecting both the exterior and interior surfaces of the specimen.

Evaluation Criteria: The standard provides criteria for determining whether the test specimen has passed or failed. This could include factors such as the amount of water penetration, location of any water intrusion, and any other specified performance parameters.

Reporting: AAMA 501.2 typically requires documentation of the test results, including details about the test conditions, any observed failures, and whether the specimen met the specified performance criteria.

Overall, the AAMA 501.2 test is an important evaluation tool for manufacturers of windows, doors, and skylights. It helps ensure that these building components can withstand different levels of water exposure, which is crucial for maintaining the integrity and performance of a building envelope.

AAMA 502 – Voluntary Specification for Field Testing of Newly Installed Fenestration Products

The AAMA 502 specification is used to test the performance of newly installed fenestration products for air leakage and water penetration. It’s used to ensure minimalized air and moisture penetration rates on newly installed windows / glazing systems.

AAMA 502 is a voluntary specification published by the American Architectural Manufacturers Association (AAMA) that outlines procedures for field testing newly installed fenestration products. Fenestration products include windows, doors, and skylights. This standard is designed to ensure that these products are properly installed and perform as intended in real-world conditions.

Overview of the AAMA 502 testing procedure:

Purpose and Scope: AAMA 502 provides guidelines for field testing fenestration products after installation. It helps verify that the products have been installed correctly and that they meet specified performance requirements.

Test Setup: The test involves creating a controlled environment around the installed fenestration product. This may include sealing off the surrounding area to prevent air leakage, using temporary weather seals, and installing pressure chambers.

Test Pressures: The specification outlines specific test pressures that should be applied to the fenestration product. These pressures are based on factors like building height, location, and the type of fenestration product being tested.

Test Procedure: The test typically involves using a calibrated fan to pressurize or depressurize the test area. The fan is used to create a pressure differential across the fenestration product, simulating the effects of wind pressure.

Data Collection: During the test, various measurements are taken to assess performance. This may include air leakage rates, water penetration resistance, and structural integrity.

Acceptance Criteria: AAMA 502 provides specific criteria for determining whether the fenestration product passes or fails the test. This could include factors such as allowable air leakage rates, resistance to water penetration, and structural performance requirements.

Reporting: After the test is completed, a report is generated documenting the test conditions, measurements taken, and the results. This report is important for record-keeping and may be required for compliance with building codes or industry standards.

Remediation: If the fenestration product fails the test, appropriate measures may need to be taken to address the issues identified. This could involve reinstallation, adjustment, or replacement of the product.

AAMA 502 is valuable for both manufacturers and contractors as it helps ensure that fenestration products are installed correctly and meet performance standards. By conducting field tests, potential issues can be identified and addressed before they become more significant problems.

AAMA 503 – Field Testing of Newly Installed Storefronts, Curtain Walls, and Sloped Glazing Systems

The AAMA 503 specification is used to verify air infiltration and water penetration performance of newly installed fenestration products, including windows, storefront systems, curtain walls, window walls and skylights.

AAMA 503 is a standard published by the American Architectural Manufacturers Association (AAMA) that provides guidelines for field testing newly installed storefronts, curtain walls, and sloped glazing systems. These systems are crucial components of building envelopes, and this standard ensures they are properly installed and perform as intended in real-world conditions.

Overview of the AAMA 503 testing procedure:

Purpose and Scope: AAMA 503 outlines procedures for field testing storefronts, curtain walls, and sloped glazing systems after installation. The purpose is to verify that these systems have been installed correctly and that they meet specified performance requirements.

Test Setup: The test involves creating a controlled environment around the installed system. This may include sealing off the surrounding area to prevent air leakage, using temporary weather seals, and installing pressure chambers.

Test Pressures: The specification provides specific test pressures that should be applied to the installed system. These pressures are based on factors like building height, location, and the type of system being tested.

Test Procedure: The test typically involves using a calibrated fan to pressurize or depressurize the test area. The fan is used to create a pressure differential across the system, simulating the effects of wind pressure.

Data Collection: During the test, various measurements are taken to assess performance. This may include air leakage rates, water penetration resistance, and structural integrity.

Acceptance Criteria: AAMA 503 provides specific criteria for determining whether the installed system passes or fails the test. This could include factors such as allowable air leakage rates, resistance to water penetration, and structural performance requirements.

Reporting: After the test is completed, a report is generated documenting the test conditions, measurements taken, and the results. This report is important for record-keeping and may be required for compliance with building codes or industry standards.

Remediation: If the installed system fails the test, appropriate measures may need to be taken to address the issues identified. This could involve reinstallation, adjustment, or replacement of components.

AAMA 503 is crucial for ensuring that storefronts, curtain walls, and sloped glazing systems are installed correctly and meet performance standards. By conducting field tests, potential issues can be identified and addressed before they become more significant problems.

ASTM E783 – Standard Test Method for Field Measurement of Air Leakage Through Installed Exterior Windows and Doors

The ASTM E783 standard is used to determine the air leakage rate of installed exterior windows and doors under specified static air pressure differences. The testing is performed by sealing a chamber to the interior or exterior face of the test specimen, supplying or exhausting air from the chamber at a rate required to maintain the specified test pressure, and measuring the air flow lost or gained across the testing chamber.

This test is intended to measure air leakage associated with the assembly and not the leakage through the openings and adjacent construction.

ASTM E1105 – Standard Test Method for Field Determination of Water Penetration of Installed Exterior Windows, Skylights, Doors, and Curtain Walls, by Uniform or Cyclic Static Air Pressure Difference

The ASTM E1105 Standard is a standard procedure for determining the resistance to water penetration under uniform or cyclic static air pressure differences of installed exterior windows, skylights, curtain walls, and doors. The air-pressure differences acting across a building envelope vary greatly. These factors should be considered fully prior to specifying the test pressure difference to be used.